Metal Stamping Ingenuity

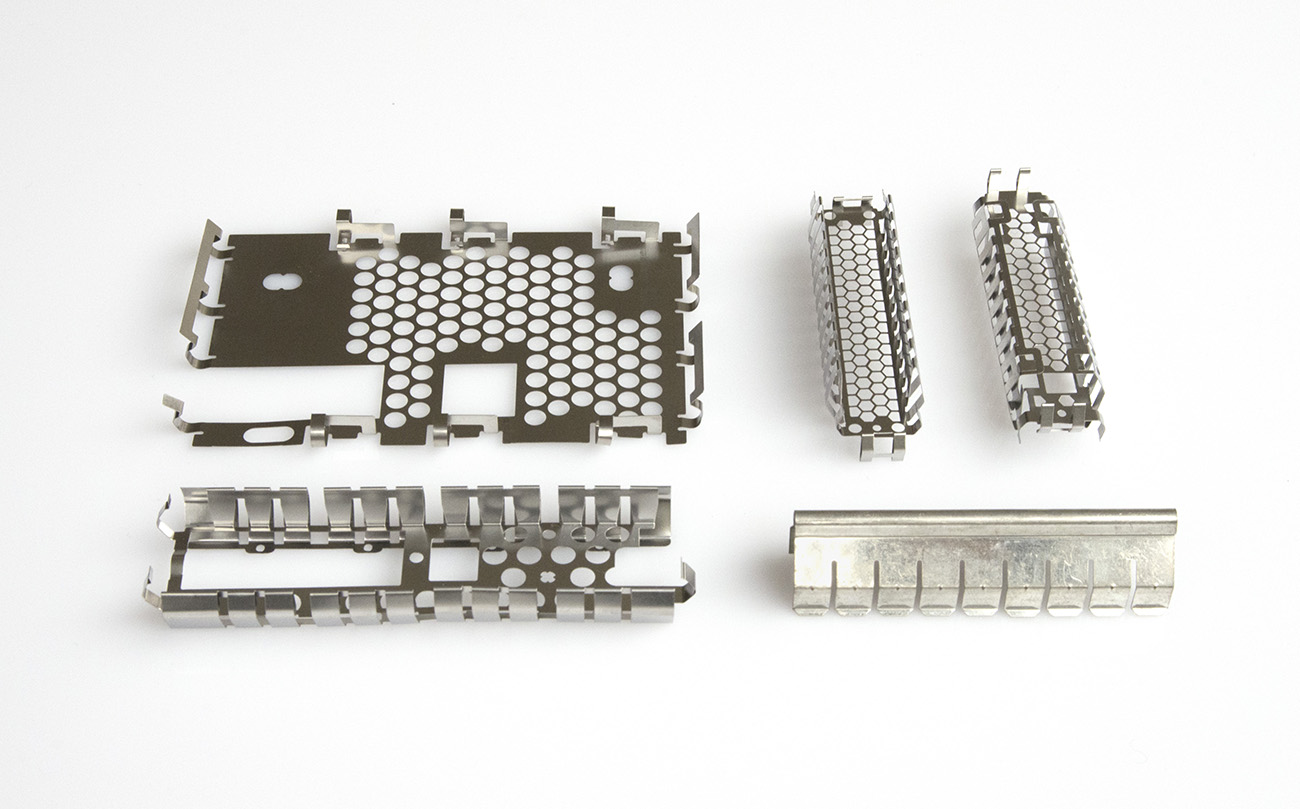

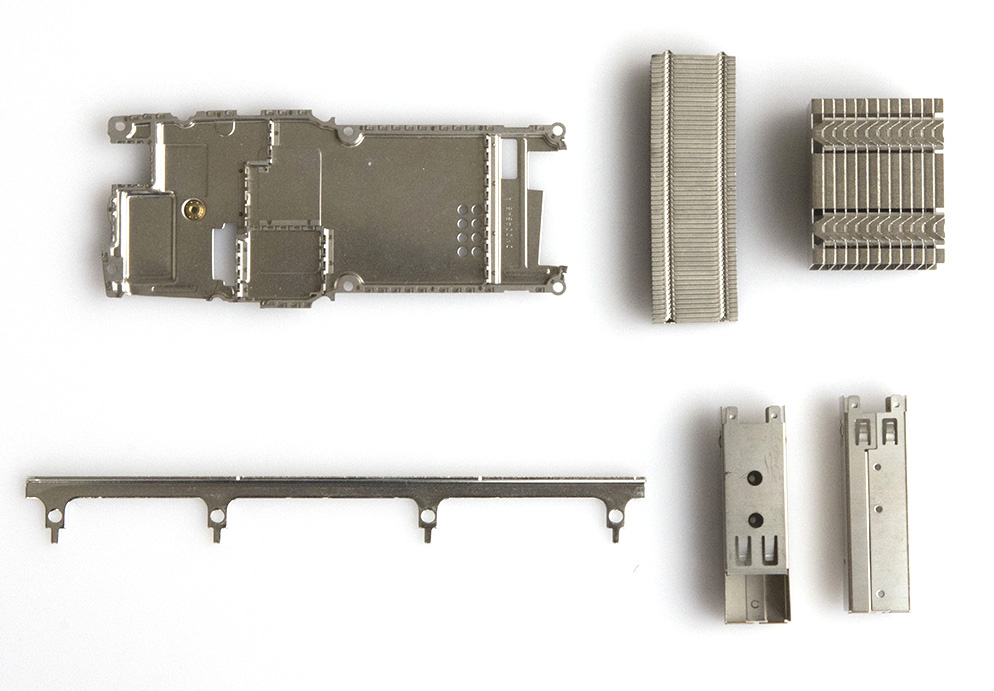

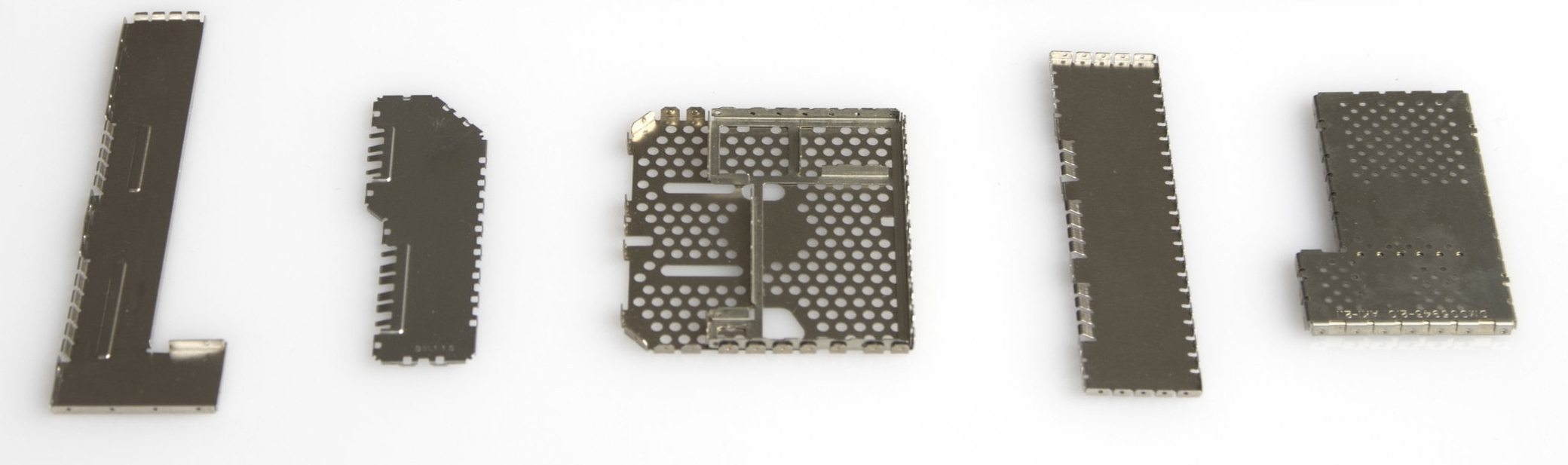

Board-Level Shielding and Electronics

AK Stamping specializes in complex precision metal stampings for electronic devices and excels in offering custom components for a range of shielding requirements. AKS products can be found in devices from the world's leading manufacturing.

Today's electronics industry demands shielding components that are thinner, lighter and more effective than ever before. AKS has responded to these challenges with innovative materials and production techniques, from precision metal stamping to 100% automated packaging.

Design engineers are under constant pressure to turn designs quickly and efficiently. AKS works side by side with its clients to develop solutions that bring product to market quickly and efficiently, offering robust product design support, materials recommendation, quick turn prototyping, advanced tooling, and high quality progressive die stamping.

AK Stamping has in-depth experience with a variety of EMI/RFI thermal shielding requirements. From design to prototype to automation and high volume manufacturing, AK Stamping effectively manages all aspects of a project to provide cost-effective solutions and ensure innovations speed to market.

AKS is the leading manufacturer of board level shields offering;

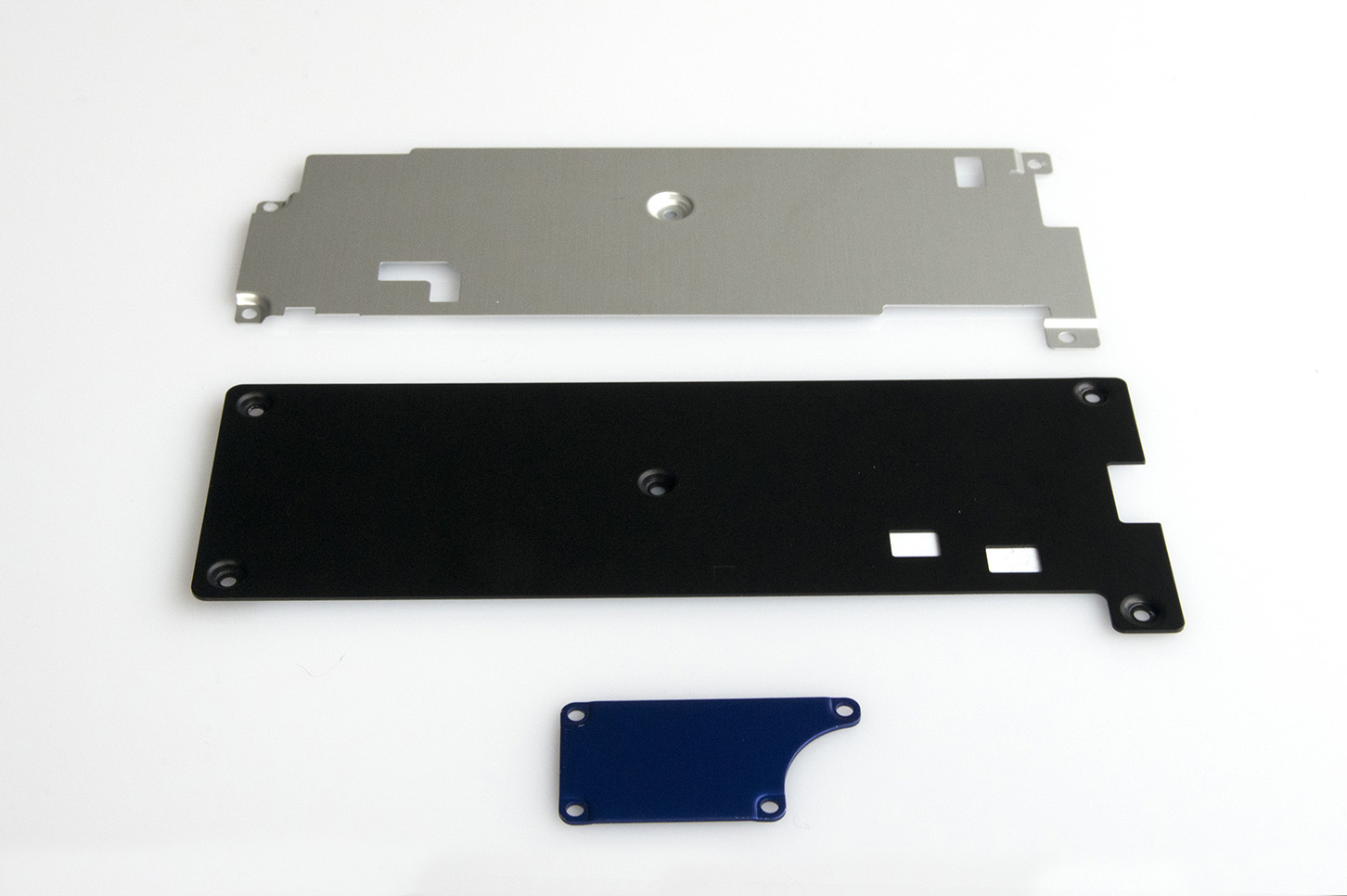

AKS patented and proprietary solderable aluminum alloys with the following advantages compared to traditional shielding materials:

Reduced weight

Improved thermal performance

Scalable thermal solutions, by adding stacked stamped heat-sink fins and TIM material for added thermal benefits

Aluminum alloy coatings in tin, copper, nickel as well as our exclusive dielectric coating

Patented 3 piece board level shields with our integrated thermal solutions

A fully automated shield manufacturing process from stamping, cleaning to in-line coplanarity checking and packaging and;

Automated and inline label, dielectric laminates and TIM assembly as well as our pre-plated dielectric coatings

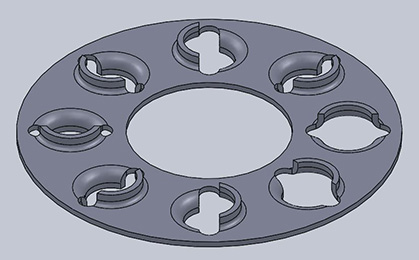

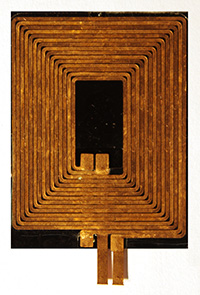

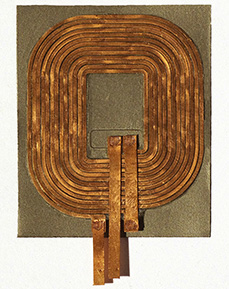

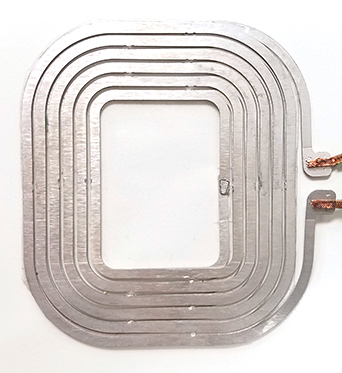

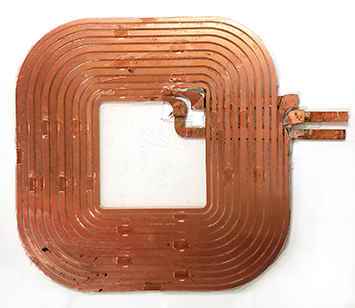

Wireless Charging

AK Stamping now offers stamped, wireless charging coils and antennas. Designed as drop in replacements for wound or bent wire TX coils and wound wire or FPC Receiver coils, the benefits of AKS patent-pending, stamped coils include greater charging efficiency and reliability, while promising reduced cost and thickness for many applications.

AKS is ready to support all custom antenna and coil solutions now, along with WPC (Qi) and multimode WPC/PMA compliant charging coils available for order.

Wireless Charging Receiver Coils (Inductive)

Wireless Charging Transmit Coils (Inductive)

Resonance Stamped Coils for Wireless Power

Features Include:

Available to suit specific electrical and mechanical requirements

Resistance and inductance tested

Available with and without Ferrite Shield

Patent Pending

Inductive charging coils for phones and tablets

Industry leading thinness for slim design requirements

Suitable for Dual Mode (WPC and PMA) applications

Low DC Resistance for high efficiency and low thermal loading

Thermal shock tested, robust construction

|

Image |

Manufacturer Part Number |

Function |

Inductance |

DC Resistance (DCR) |

Size |

|

A2324 |

Receiver |

8.1 µH |

145 mΩ |

39 mm x 30 mm x .55 mm |

|

A2330 |

Receiver |

10.3 µH |

185 mΩ |

42.2 mm x 33.2 mm x .55 mm |

|

A2306 |

Receiver |

11.2 µH |

125 mΩ |

53.5 mm x 46.6 mm x 2.6 mm |

|

A2321 |

Receiver |

6.9 µH |

136 mΩ |

36.1 mm x 31.1 mm x .55 mm |

|

A2311 (A11) |

Transmitter |

6.3 µH |

50 mm x 41.8 mm x 2.5 mm |

|

|

A2301S |

Transmitter |

6.8 µH |

105.1 mΩ |

52.8 mm x 75.7 mm x 0.89 mm |

|

A2309 |

Transmitter |

4 µH |

169.6 mΩ |

43 mm x 43 mm x .56 mm |

|

A2384 |

Receiver |

4.4 µH |

192.2 mΩ |

43 mm x 43 mm x 0.18 mm |

|

A2391 |

Transmitter |

5.8 µH |

112.9 mΩ |

48.3 mm x 43.3 mm x .55 mm |

|

A2365 |

Receiver |

8.6 µH |

331.4 mΩ |

48.3 mm x 59.7 mm x 0.25 mm |

ASSOCIATED PARTNERS

Resources

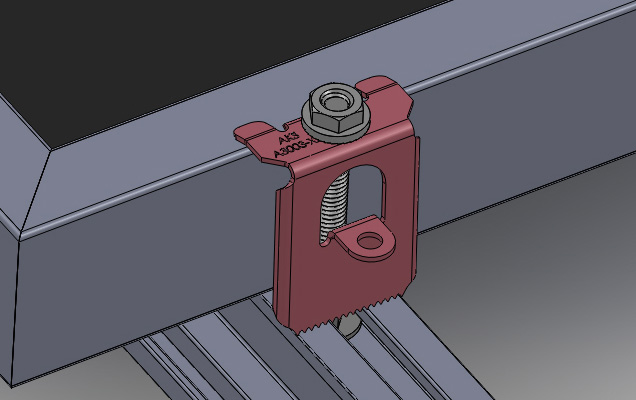

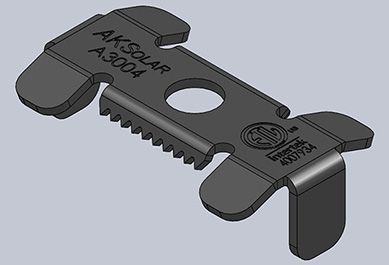

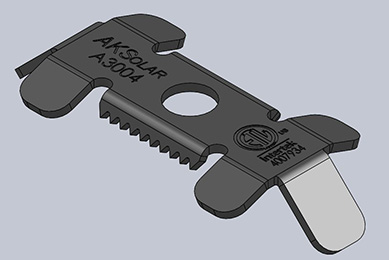

AK Solar, a Division of AK Stamping, provides innovative and cost effective solutions for PV module bonding and grounding. AKS’ lineup of solar products can reduce installation balance of system costs by simplifying installation. Our patented products offer unmatched durability and compatibility, working with top and bottom mount racking systems. In-house design and engineering reduce costs and response times.

Grounding Spacers

Conductive Mid-Clamps

Conductive End-Clamps

Grounding Clips

PV Bonding Jumpers

Grounding Terminals

Bonding jumpers, grounding spacers, mid- and end-clamps that are recognized to UL Standard 2703 and ETL listed to UL Standard 467.

AK Solar's bonding and grounding solutions offer the following key features:

All clamps have strong, sharp teeth to cut through surface coatings and oxides

Reinforced sidewalls on End-Clamps

Up/down extrusions to bond vertically on Grounding Spacers

Universal slide and fasten design of Grounding Spacer for fast assembly

316L material for ultimate corrosion resistance

Guides on Mid-Clamps to secure module in place, without breaking module glass

Tabs for easy locating on Mid-Clamps

Solar Hardware Solutions

Solar Mid-Clamps and End-Clamps

Solar Bonding Jumpers

Solar Grounding Spacers

Medical

AK Stamping understands the unique challenges of the medical device market. Strong capabilities in engineering and product development, prototyping, in-house tool build, precision metal stamping and quality guarantee results that are in keeping with the changing needs of the medical field. AK Stamping's commitment to developing innovative solutions brings products to market on-time and on-budget, with the highest quality. AK Stamping services OEM’s and contract manufacturers in the medical market, specializing in custom components for implantable devices.

Capabilities include:

Phased Progressive die production for blanking, forming, and stamping of complex features

Thermally stabilized tools and materials for accuracy and precision

Full prototype department for quick turnaround (1-2 weeks) and R&D support

High-speed Bruderer presses capable of over 500 strokes/minute

Ability to package and assemble plastic and metal components

All processes are ISO9001 certified, ensuring top-quality, defect-free products

AK Stamping medical products Clips • Blades • Cutters • Graspers • Jaws • Tubes • Sharps • Surgical Components • Pacemaker Components • Disposables

Medical Stamping Solutions

Defense

AK Stamping is proud to serve the needs of the warfighter with a suite of small and medium caliber ammunition links. As AKS' link stamping tools are 100% designed, built, and maintained in-house, there is a focus on continuous improvement programs, which allow for manufacturing rates up to 50% faster than the competition while still meeting the challenge of MIL-1916 requirements.

AKS produces the following links in the Mountainside, NJ facility:

5.56MM M27

7.62MM M13

20MM M14A2(N)

20MM MK7

30x173MM

40MM M16A2

AK Stamping is proud to be a Veteran-Owned Small Business, serving the needs of US Armed forces and our allies around the world.

Military Stamping Solutions

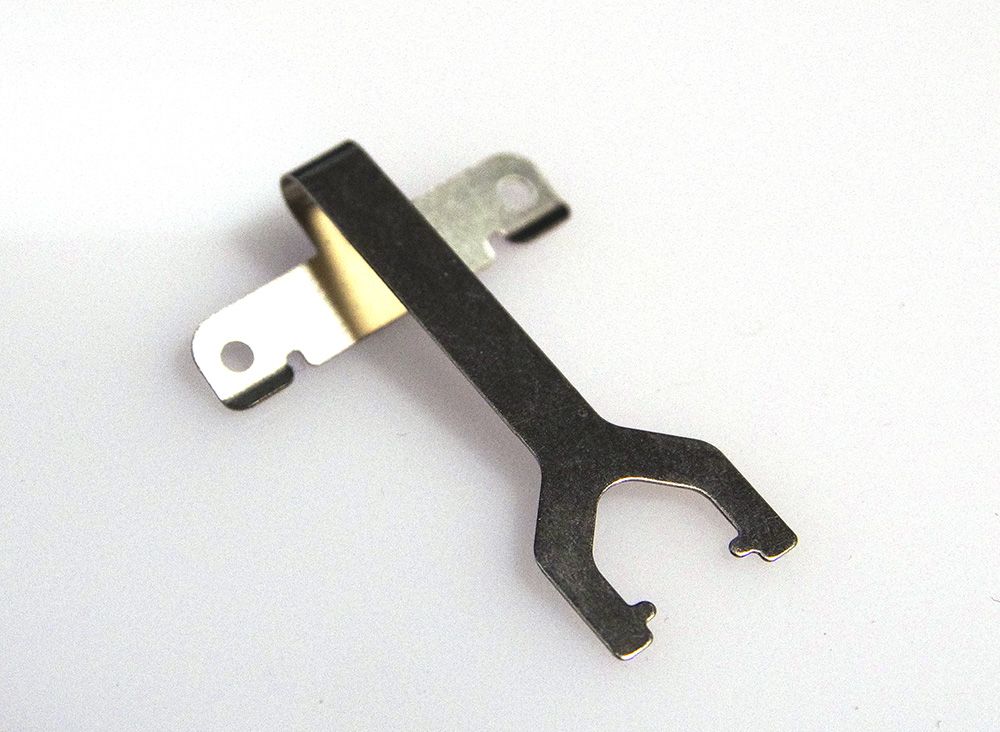

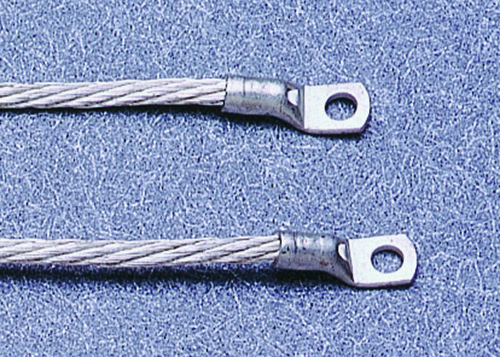

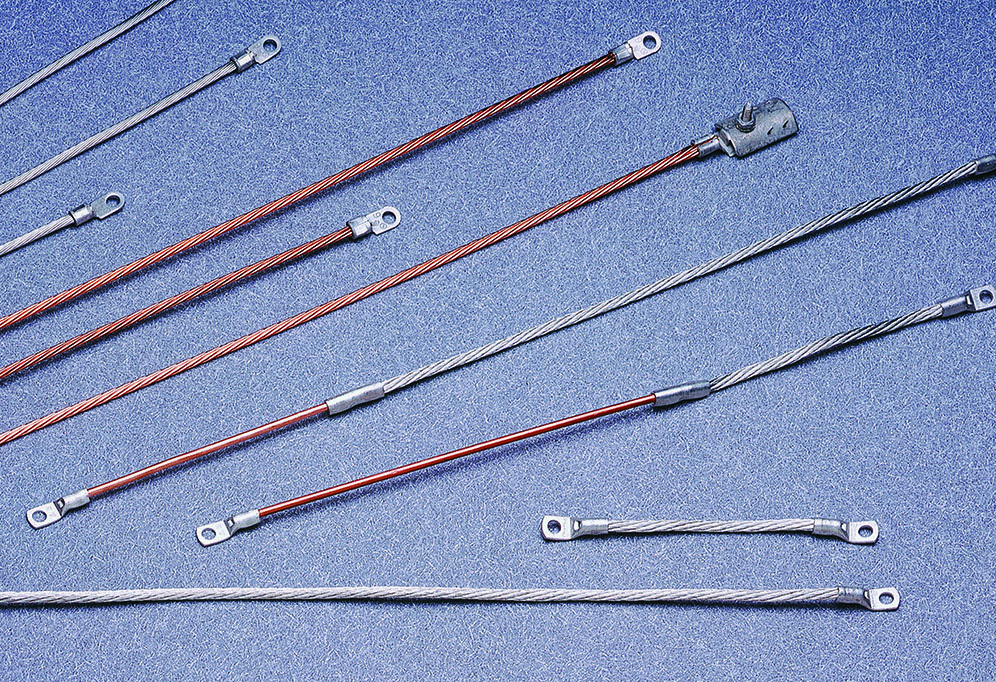

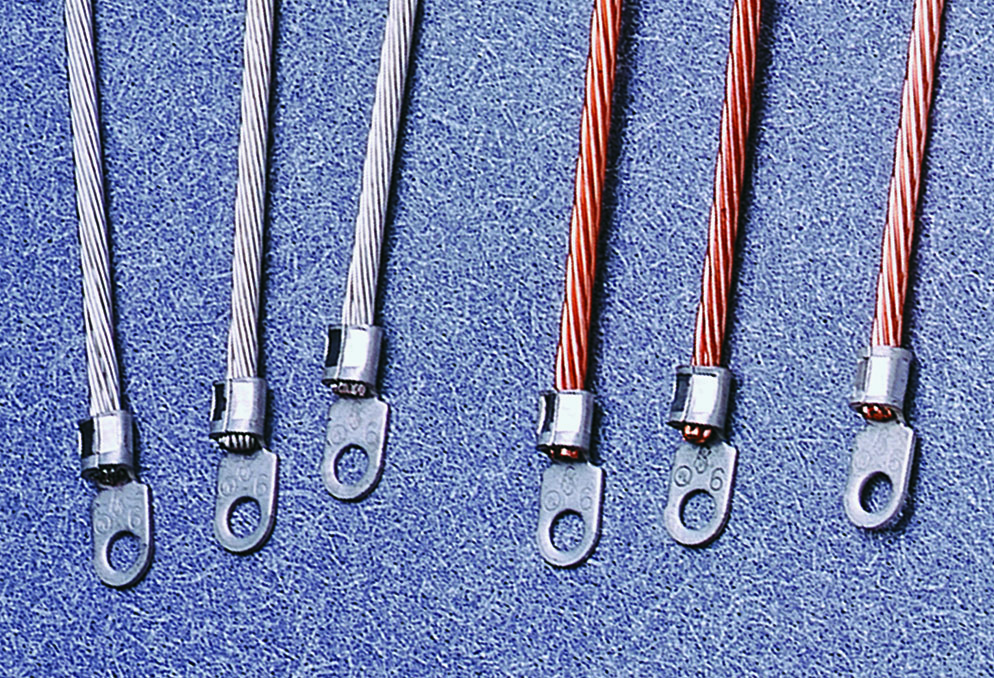

Telecom Hardware

AK Stamping Company is a leading supplier of cost-effective and functional solutions in bonding and grounding hardware for outside plant (OSP) applications. AKS offers the following telecom products:

Bond Assemblies

Bond Braids

Bond Clamps

Connectors *

Drop Wire Clamps

Ground Clamps *

Ground Straps *

* UL Listed

AK Stamping's tested products exceed Bellcore specifications and feature the only cable shield bonding clamps in the industry to meet the field simulation of cable bonding clamp "Use and Reuse". Extensive inventory forecasting accommodates high-usage periods. AK Stamping has an international distribution network in Central America, South America and Europe.

Telecom Hardware Solutions

Telecom Products

Telecom Product List and Part Numbers

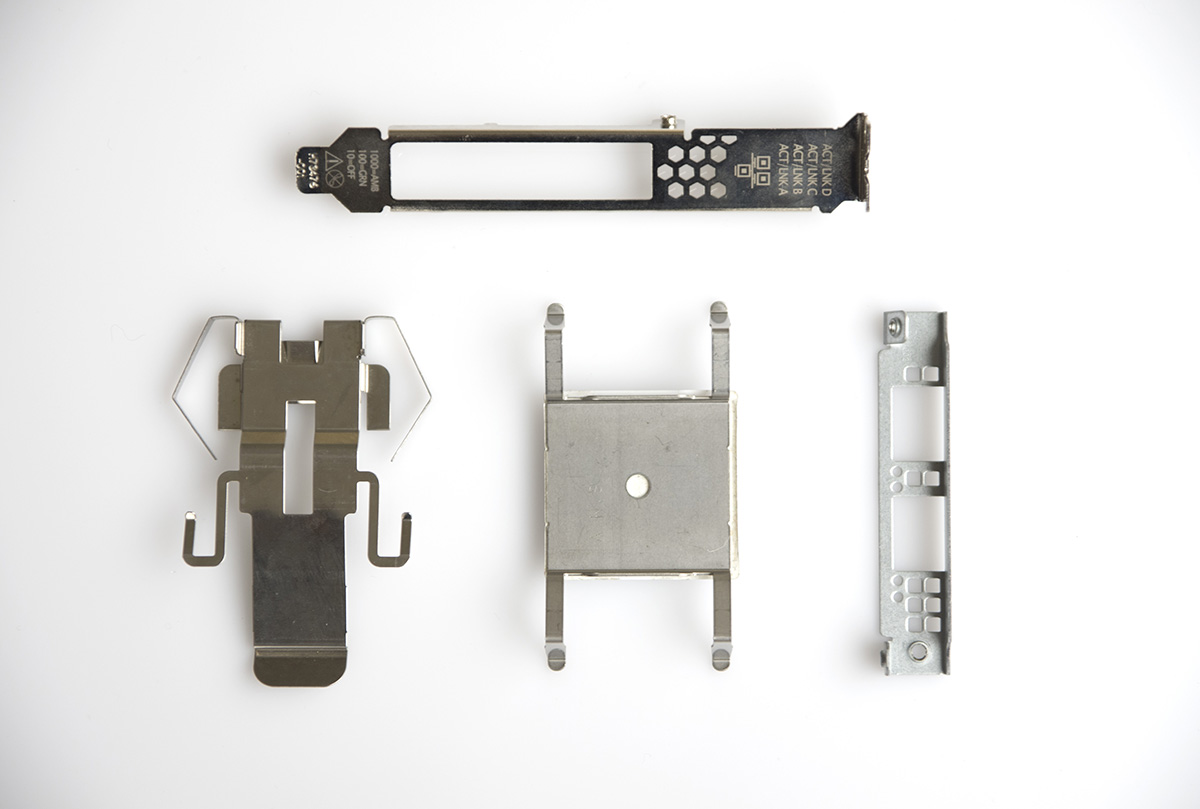

Globe Brackets

Globe Manufacturing Sales, Inc., a division of A.K. Stamping Company, Inc., is the leading supplier of brackets to the computer and electronics industry since 1980. Offering top value and premium quality, Globe has tooling for over 1000 different types of brackets. With sophisticated engineering, manufacturing and sourcing operations in North America and Asia, Globe delivers premium quality and economical brackets. Our brackets and tailstock are fully customizable and are available with an array of holes and cutouts to connect to any peripheral.

Please visit WWW.GLOBEBRACKETS.COM for specific product information.