State Of The Art Processes

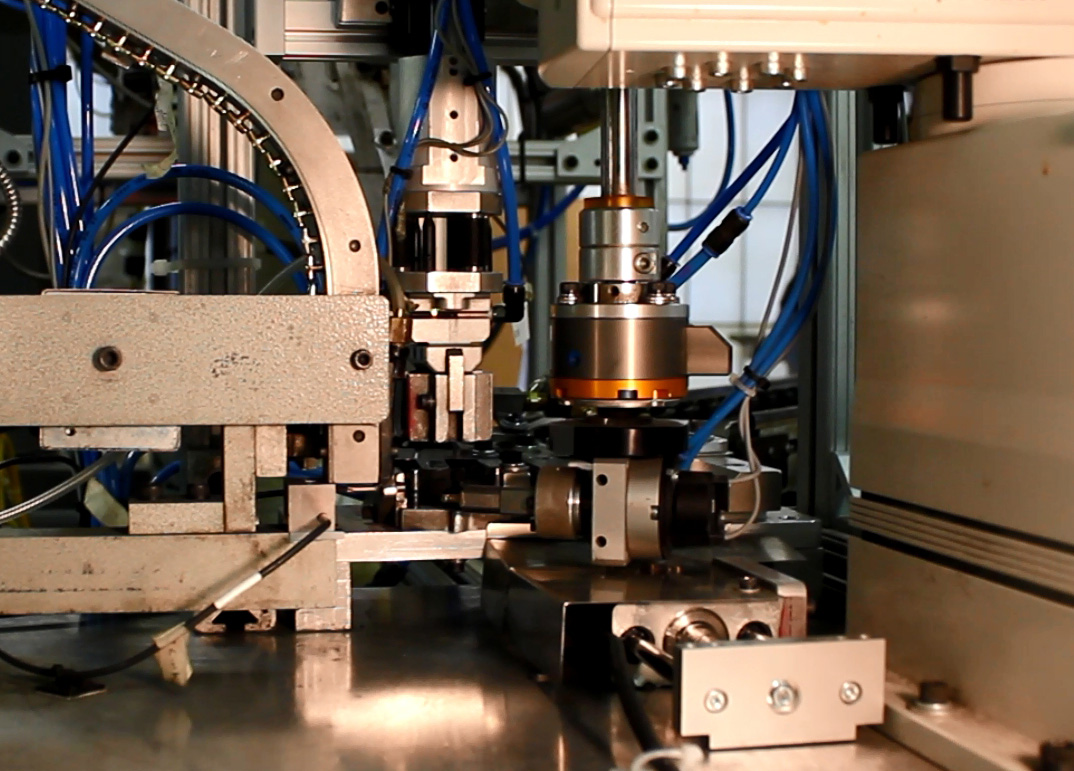

Tooling

Quality stamping tools are key to a quality metal stamping. This principle is the foundation of AK Stamping's success, and is reflected in every aspect of its tooling operations, all of which are performed in-house.

To design stamping tools, AKS utilizes the latest CAD software tools to create files that are fed directly to the Wire EDM and CNC machining centers, without operator intervention. After the components are finished, skilled toolmakers perform the final tooling assembly and fitment. This process, developed at AK Stamping's US HQ, has been fully scaled at the China location as well.

The result? Industry-leading tooling kickoff to completion times, and metal stampings of unmatched quality.

In metal stamping, there are 3 primary types of tooling processes:

1. PROTOTYPE TOOLING

3-5 days typical lead-time using Toggle press tooling

Soft tools, tool life expectancy - 1K hits

2. STAGE TOOLING

3 weeks typical lead-time hydraulic tool sets

Can build blanking tools or use prefabricated blanks

Part mods easier to accommodate

Tool life expectancy - 50K hits

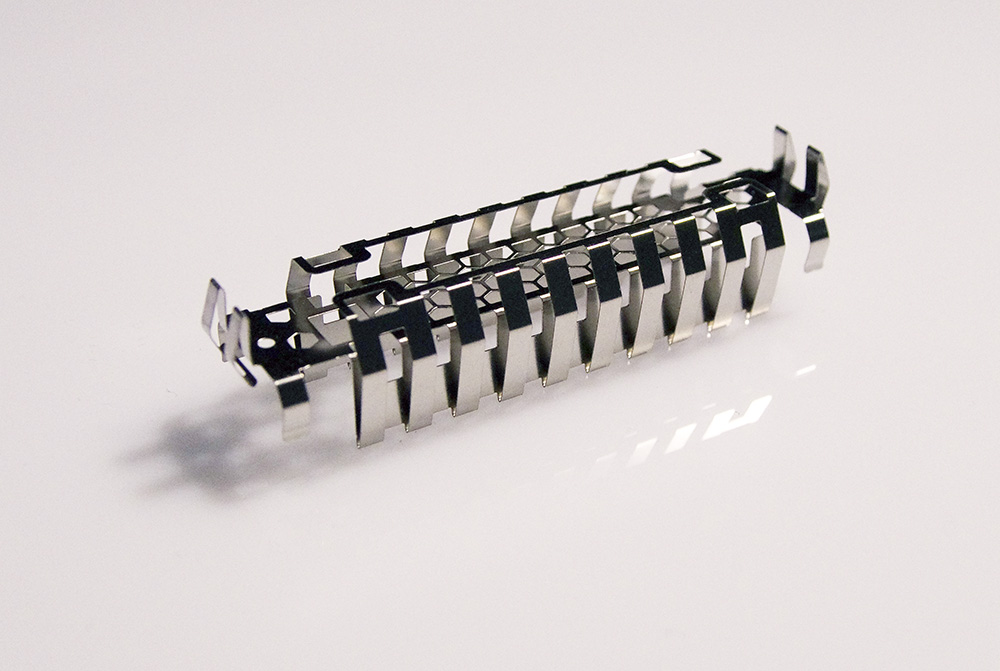

3. PROGRESSIVE TOOLING

7-plate module tool concepts

Modifications available but fixed to X, Y, Z dimensions

Approximately 3-4 week lead-time

AK Stamping offers all 3 types of tooling processes, all designed and built in state of the art facilities to exacting specifications.

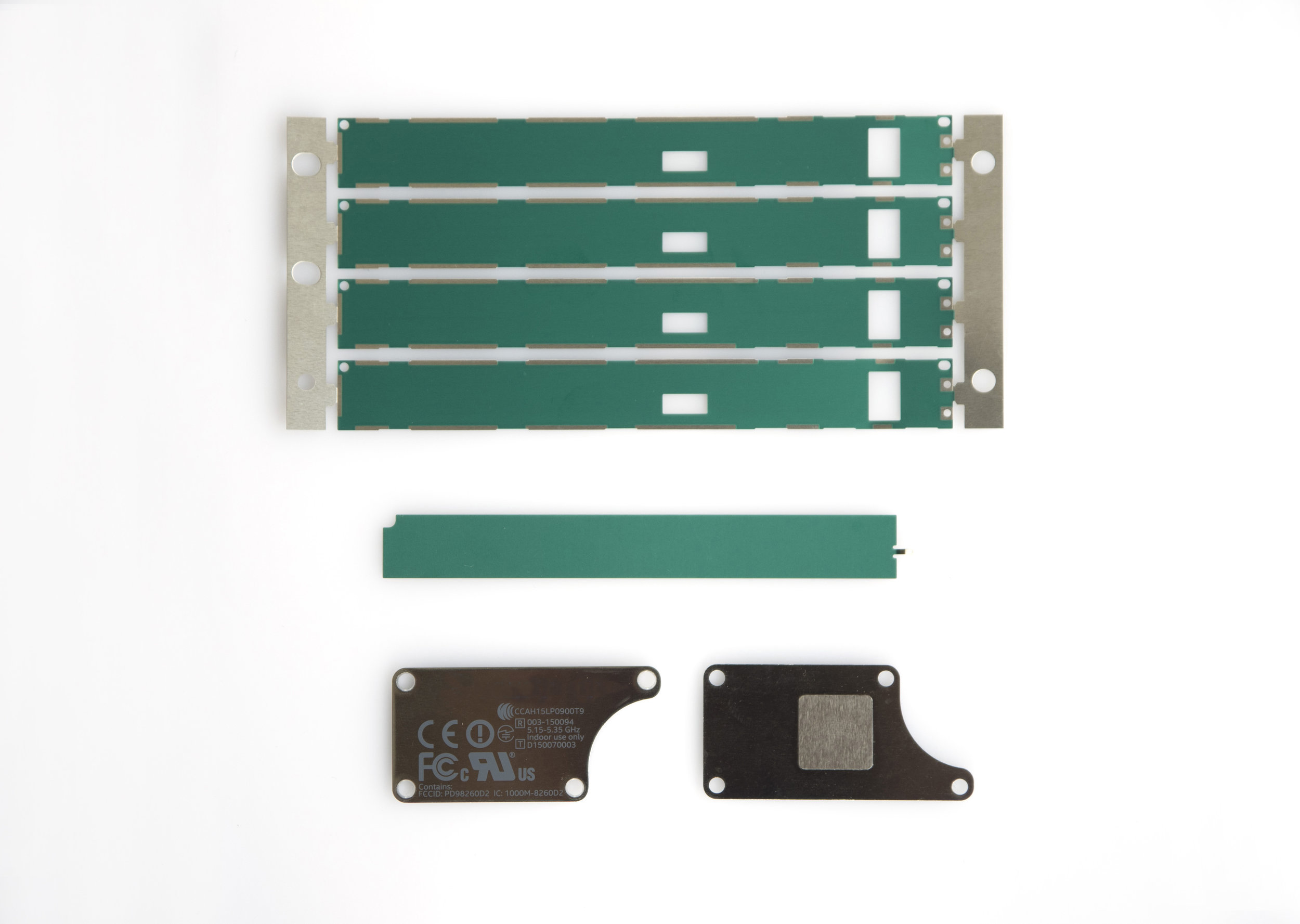

Stamping

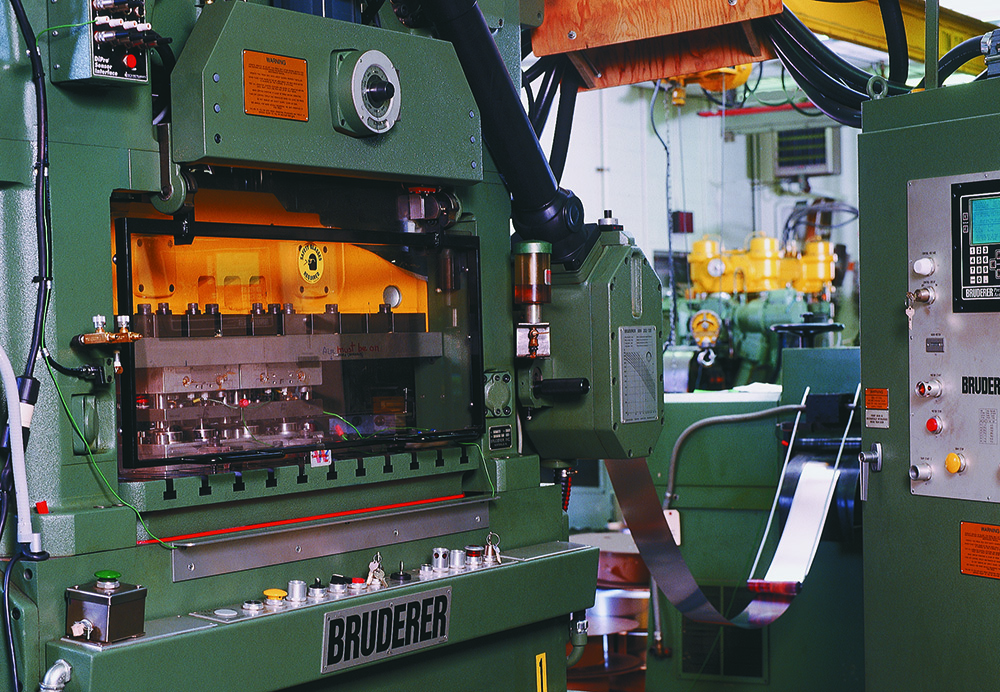

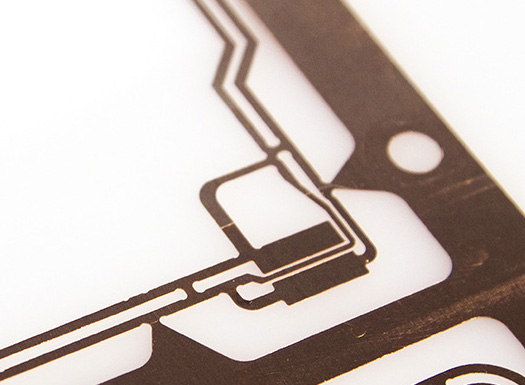

Whether it be stage tools or fully progressive dies, high-carbon steels or brass, AK Stamping offers a variety of metal stamping options. AKS' speciality is precision metal stamping run on progressive die tooling. The Bruderer and Aida presses are capable of handling materials from 0.0025" (0.07mm) up to 0.250" (6.3mm). AKS currently produces precision metal stampings for the Electronics, Medical, Defense, Automotive, Alternative Energy and Telecommunications industries.

Some of the alloys frequently stamped include:

Stainless steels (S301, S302, S304, S316)

Mild steels (G1010)

High-carbon steels (G1050)

Brass (C23000, C25000)

Nickel silver (C75210)

Titanium (6AI-4V and others)

AK Stamping has the capability to do high-speed stamping at over 1,000 parts per minute, with optional reel-to-reel material handling.

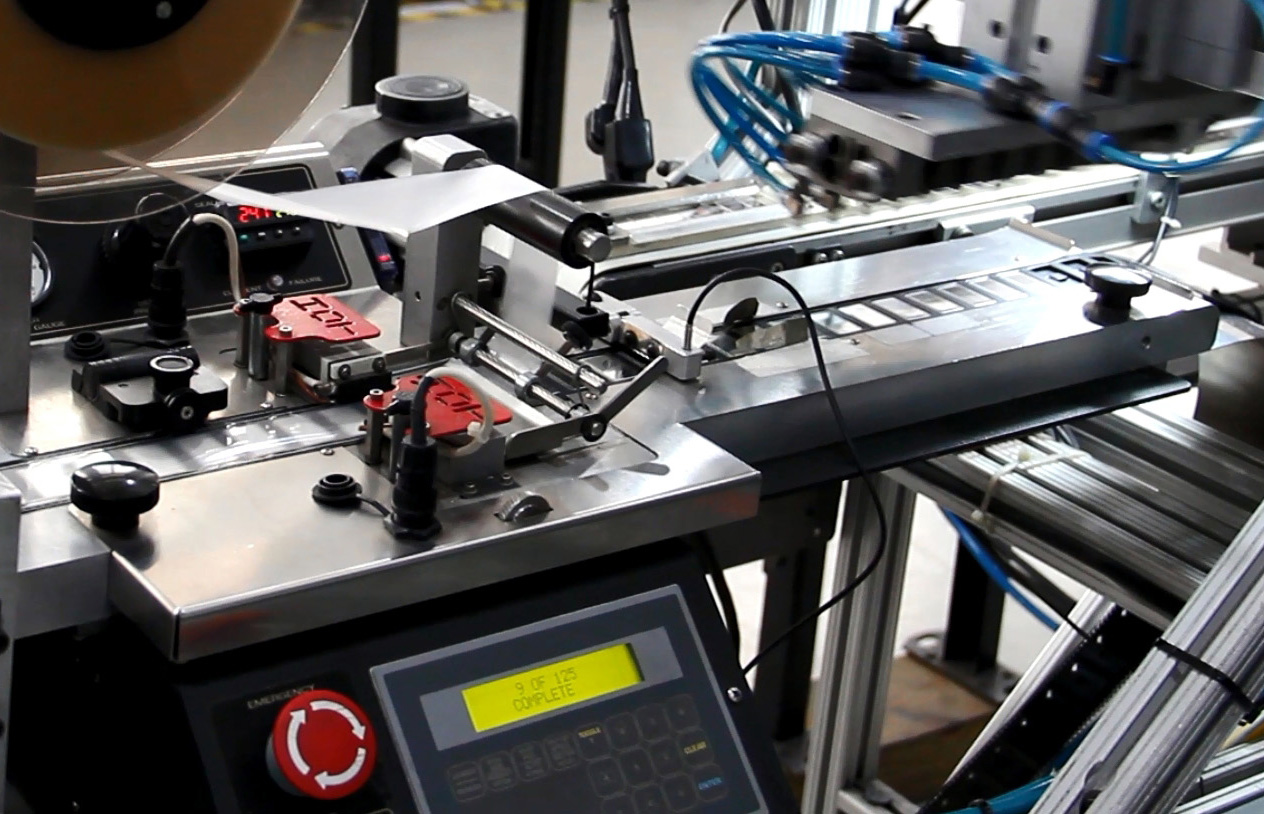

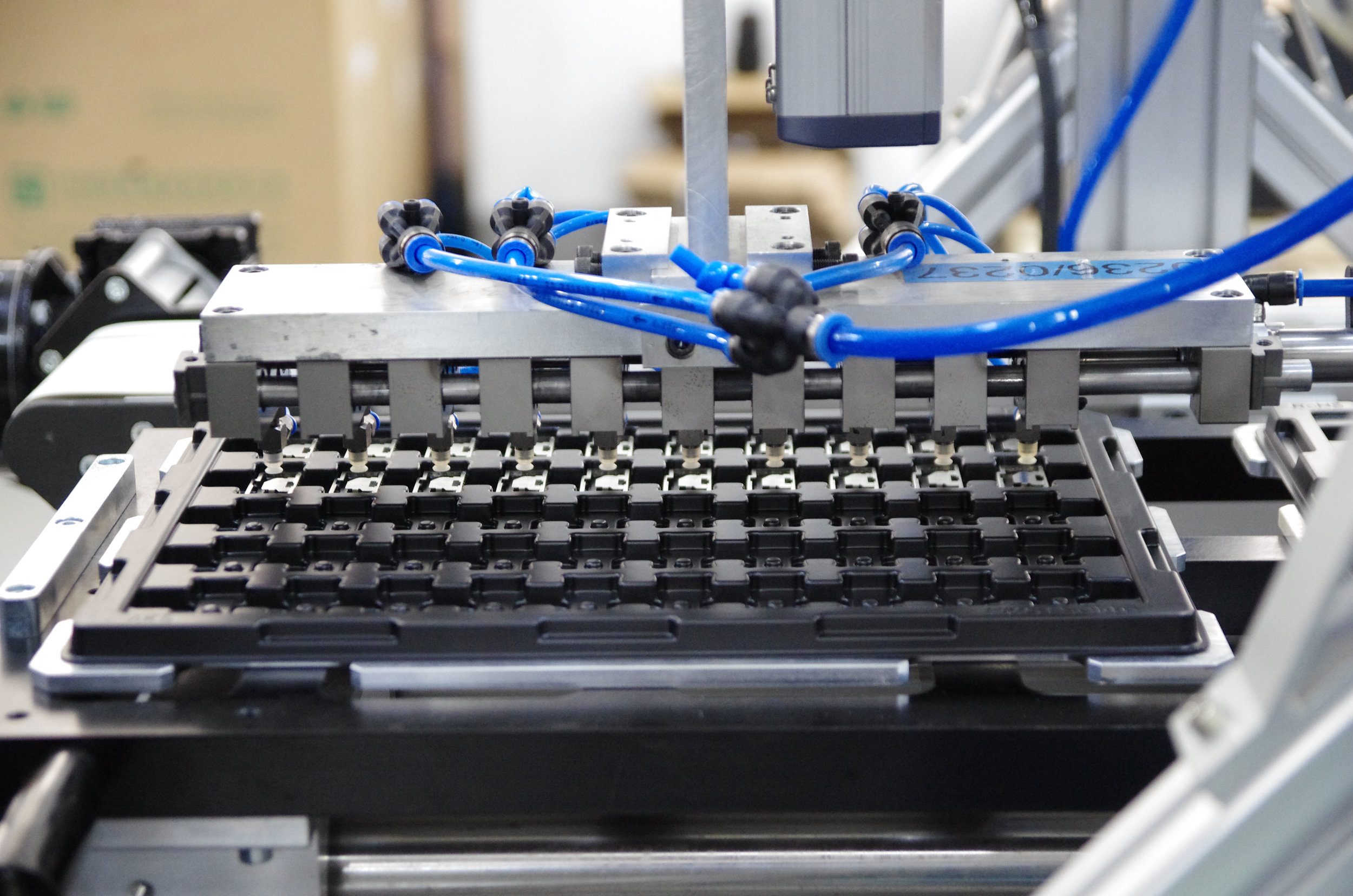

Assembly

AK Stamping understands that metal stamping is often only a portion of the client's overall needs. To that end, AKS offers a variety of assembly technologies and other value added services to reduce total costs, including:

In-die assembly

Post-stamping robotic assembly

Welding (resistance, laser, ultrasonic)

Staking (heat and mechanical)

Auto Packaging: Tray, Tape & Reel, Bulk

Auto Assembly for Mylar, TIM, Ferrite, Insulators, labels, etc

Auto Component Assembly

Pad printing

Laser marking

100% inspection by vision system

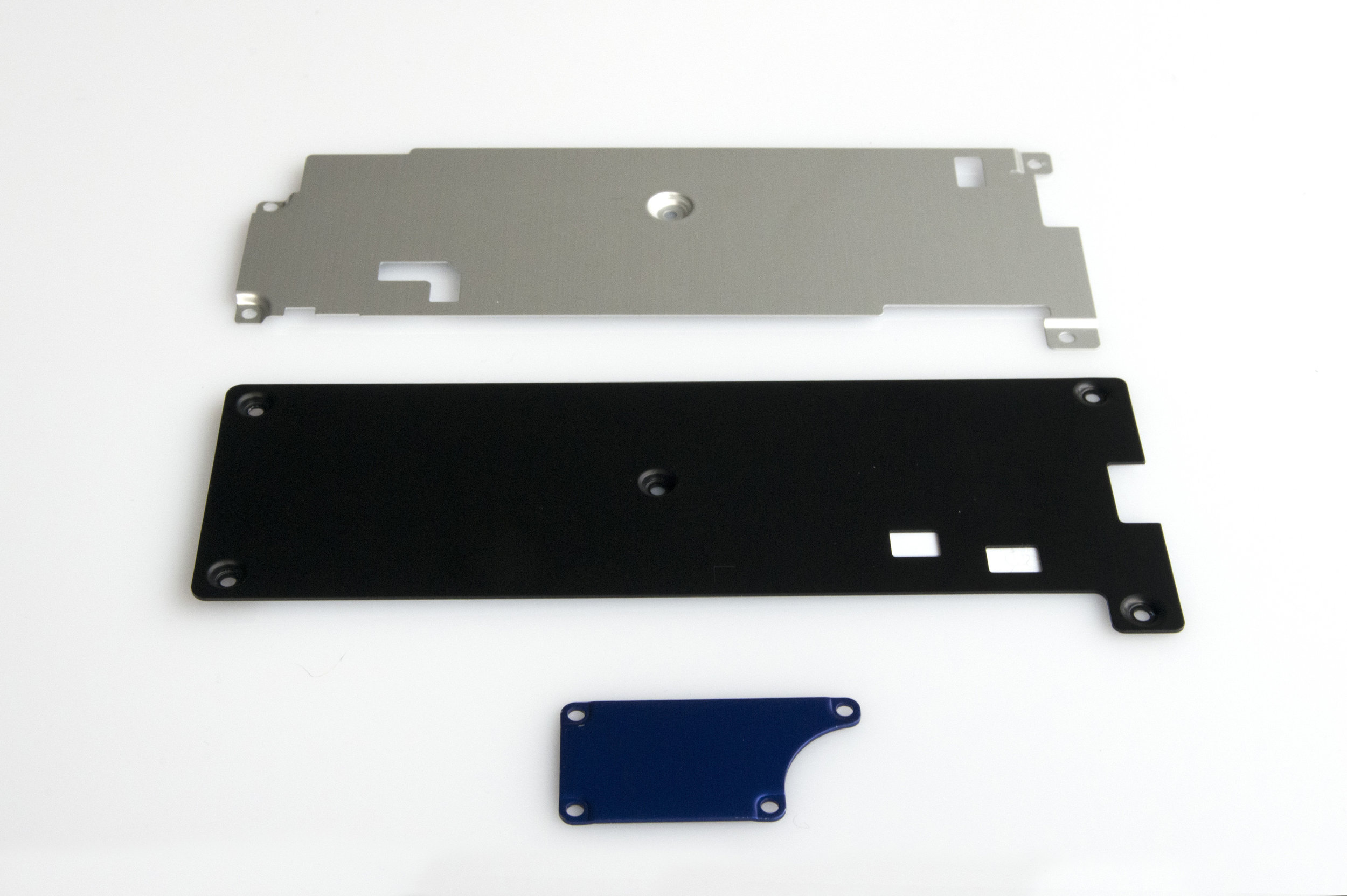

Finishing

AK Stamping offers a variety of finishing options for your products, including:

Mechanical deburring, electro-polishing, chemical deburring

Anodizing, precious metal plating, passivation, powder coating

Material heat treating, fixture and bulk

Multi-color pad printing and oline ink jet date coding

Laser marking

![02626_Prog Die_exploded[13].JPG](https://images.squarespace-cdn.com/content/v1/52f1b8dce4b0c7721b5fcd55/1496851370085-HRFKDBJDQZJLR5RQKNR3/02626_Prog+Die_exploded%5B13%5D.JPG)

![02626_Prog Die_top[14].JPG](https://images.squarespace-cdn.com/content/v1/52f1b8dce4b0c7721b5fcd55/1496851389766-XPC9EXJQ1QV1X6PT89J5/02626_Prog+Die_top%5B14%5D.JPG)